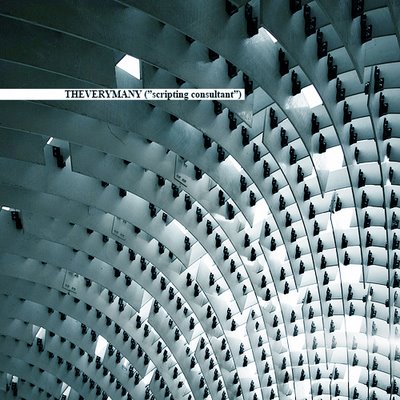

080406_APERIODIC VERTEBRAE v2.0.2

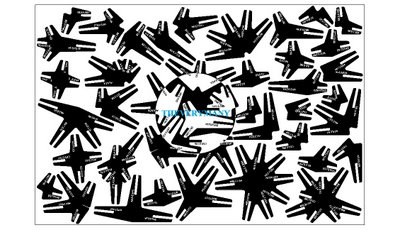

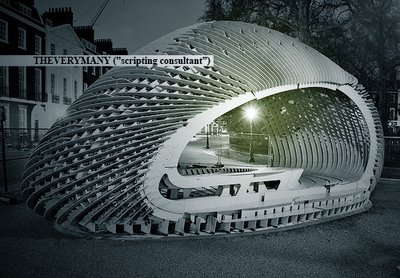

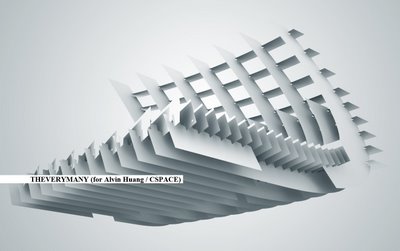

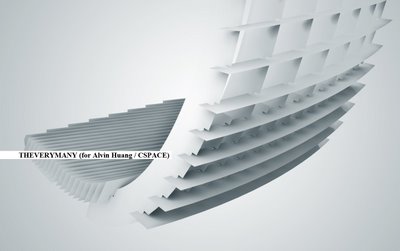

Finally back from several events and wanderings all over the place (Paris, New York, Frankfurt, Strasbourg, Barcelona,...) - here is a first update on the prototype THEVERYMANY produced for Node08 / Frankfurt.

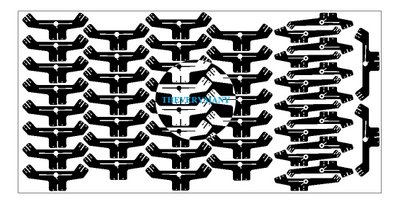

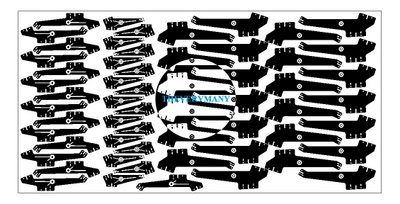

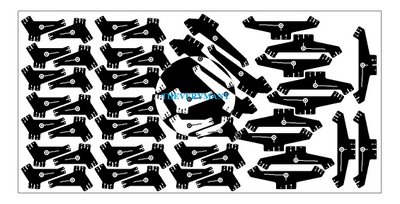

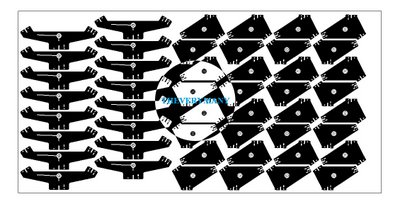

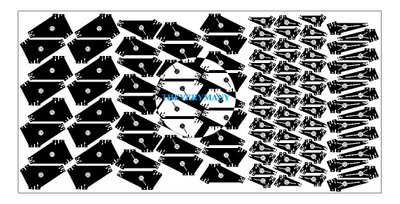

Its assembly has this time been a success (and hughe improvement since v1.0) as it took less than 24 hours & 2 people & 2 laptops to (re-)assemble the 360 panels and 320 nodes...

Once more demonstrating us "one better spend its time within development embedding assembly logic rather than waiting the material world to solve the fuzzines..."

(I will update the "information modeling" improvements on the previous post more focused on the digital back bone approach of the piece...)

"Aperiodic Vertebrae v2.0"

THEVERYMANY (project team: Marc Fornes / Skylar Tibbits)

NODE08 (www.node08.vvvv.org)

April 5th - 12th, Frankfurt / Germany

Many thanks to Eno Henze (http://www.enohenze.de/) & the entire VVVV team (http://vvvv.org) for their invitation & sponsorship

Also many more thanks to our sponsors for the piece:

- Quadrant EPP USA, Inc. (www.quadrantepp.com) > provided us sheets of polyethylene (3/16″ thick)

- Continental Signs (www.continentalsigns.net) and Jared Laucks > CNC cut of the panels

- Dick Dunlop > laser cut of the 320 unique connections (3/16″ acryclic)

Labels: aperiodic, aperiodic tiling, architecture, cnc, digital manuctacturing, installation, laser cutting, Node08, rhinoscript, theverymany